Limits to MRL Hydros

February 7, 2019

Manufactured One Piece

March 11, 2019

Modular Solution to Labor Crunch

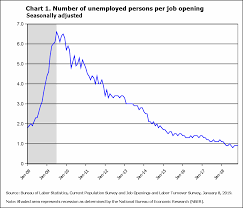

The labor market is getting tighter and tighter, especially with a 3.9% unemployment rate, and actual jobs are now more plentiful than those seeking them, according to the Bureau of Labor Statistics. The Bureau is an arm of the United States Department of Labor and they track and report all things labor in the US. According to the official statistics, simply put, we have more job openings than people to fill them. This labor crunch is clearly evidenced by the most recent numbers of people filing for unemployment. It is the lowest rate since 1969 and many say it is due to employers holding on to employees because they fear not being able to find replacements. This trend is also demonstrated in a recent phone call we received at Phoenix Modular Elevator.

The phone call was from a manager of a regional elevator company that has new installations as a large part of their book of business. For the first time ever, he called us to get details on our modular solution that he had seen at a recent trade show. But strangely, it was not due to our fast installations (less than a week with standard hydraulic models), nor was it due to the price, which is usually very competitive. It was due to the fact that he was having significant difficulties in filling elevator technician positions with qualified employees in his company. That was leading to the unusual problem of people wanting elevators, the company wanting to provide them, but having no way to get them installed in any reasonable time.

As the manager started looking for solutions, he remembered us and modular quickly became the best way to provide elevators to a customer base that needed them.

But his questions were not all about installing more elevators faster. He dug deep during our conversation about quality and safety. He was not going to install anything that was substandard or less safe than what he could provide through traditional, old-fashioned elevator installation. To his surprise, he found that our high-quality commercial elevators have parts that are from solid, tried and true elevator supply companies and are always non-proprietary. This means that his crews could trust our product and get them up and running with little problem because everything from door openers (that come pre-installed) to controllers were from companies they were familiar with and liked to work with.

He also loved the fact that a modular machine room was available that comes largely finished with a tank, pump and motor already installed and ready to go once power is available. It seemed too good to be true, so he began to question safety.

Over the years, he had seen plenty of good elevator technicians forced to leave the business due to injuries usually associated with lugging around heavy rails and being forced into tight working conditions in very cramped elevator hoistways. Anyone in the elevator business can tell you it is not very kind to the back, and Tylenol is often gobbled up more often than M&M’s. He was extremely relieved to find a company that cares enough about elevator technicians to do most of the heavy lifting for them. No more rails to be installed in a vertical shaft and the car is assembled separately from the hoistway and inserted with all the wiring before it is shipped.

With all of these huge benefits, not only was he instantly sold, but he wanted to start selling them himself. We were able to provide the perfect solution to the problem of lack of qualified labor, and he found a quality solution that was not only faster to install, but safer for his employees.

If you want to become a qualified installer of Phoenix Modular Elevators, just go to this website and answer a few questions. We want to help you make elevators easy! If you have a project in mind, click the button below.