Elevator State

June 14, 2019

Earthquake Elevator

July 18, 2019

No Elevator Installation Needed

The easiest way to avoid elevator installation in a multi-story building is to not have an elevator. That was the old way of thinking. Now you can have an elevator with no installation at all through modular elevators. This modular way of building is becoming more and more popular because it is faster and safer than traditional elevator installation, largely due to the fact that the installation of the elevator is completed in a factory, under factory controls with significantly more efficiency. But before you pop the champagne corks over no more elevator installations, let’s be clear about what we are talking about.

There are two distinct steps of getting any elevator installed and running in a building; the installation of the components and then starting up the elevator. In the traditional stick- built elevator, the hoistway is constructed and then sits until power is turned on in the building. Then, an elevator technician comes in and, one piece at a time, installs the entire elevator in the enclosed hoistway. This is time consuming and dangerous. Falls through open hoistway openings, lugging around heavy rails and building an elevator car in a cramped hoistway are just the tip of the hazardous iceberg for this outmoded type of construction. Once the elevator car and a set of rails is installed with all the wiring, the elevator contractor gets the elevator running, makes adjustments,, etc.

Why We Are Different

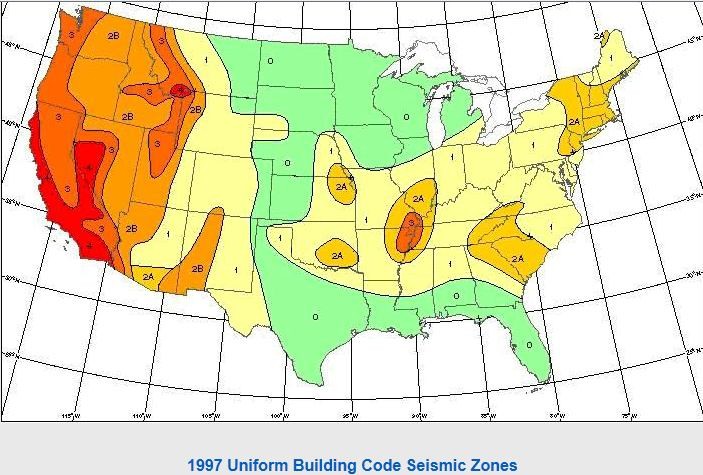

With modular elevators, we take a large part of the installation inside a factory. First, we build a fire-rated and building code-compliant elevator hoistway, regardless of seismic or hurricane zone. Then comes the installation of all of the elevator components inside the hoistway in the controlled environment of a factory. This means the high-quality elevator arrives on a truck, ready to be hoisted into place with the rails and cars already installed and perfectly aligned every time. The doors are already hung and all of the hall calls, buttons and wiring are complete. The cab is finished in any style and pre-installed, other than the flooring. In a hydraulic elevator, the jacks are even in place when the travel distance works out for an above-ground option. When travel distance is higher than allowable for above-ground jacks, the in-ground jack arrives at the time of the placement and the elevator is completely ready to receive the jack. In a Phoenix Modular Elevator – traction model, the elevator is partially pre-roped, saving time and effort as well.

So, there is much less installation once the elevator is on site because the components are already in place inside the hoistway. The elevator is already literally pre-installed.

That Does Not Mean There’s Nothing To Do

First, when the elevator arrives on site, the building (hoistway with elevator components) has to be leveled and plumbed when put into place. As I am typing this, I can feel your blood pressure starting to rise. Deep breath. Relax. Phoenix Modular Elevator has a placement team that goes out with every job and will be there to make sure everything has arrived as promised and will take charge to make sure the hoistway is placed on the pre-set anchor bolts. We will bolt it down, making it ready for the startup. If an in-ground jack is part of the plan, we will work with the elevator technician of your choice or one we have agreed on to put the jack in the ground. Simple. If it is a traction model, all of the roping is already contained in the hoistway. We will make sure they are put into place with the elevator technician.

Startup

The startup is where the elevator technician really gets going because there are some things that have to be done for the elevator to be started up (not installed). The technician or mechanic will make sure that the following is completed:

- Run the wiring to the controller. They are already run to the rest of the elevator.

- Make sure the jacks are plumb and grouted in place.

Add hydraulic oil. - Remove all shipping brackets other than those under the elevator car.

- Turn the elevator on and move the car up.

- Check for leaks.

- Take off the shipping brackets under the elevator car.

- Lower the car and check for leaks.

- Replace packing.

- Adjust the elevator to proper floor levels.

For a traction elevator, the process is largely the same other than taking the elevator ropes that are in the hoistway and running those as needed. Once they are run properly, the start up should be like any other elevator.

Lastly, the elevator technician will make sure the inspection is scheduled and fulfill the punch list items.

In the next blog, post we will run through what the general contractor or building owner should expect when the modular elevator arrives on site.