Elevator Companies

December 11, 2018

New Elevator

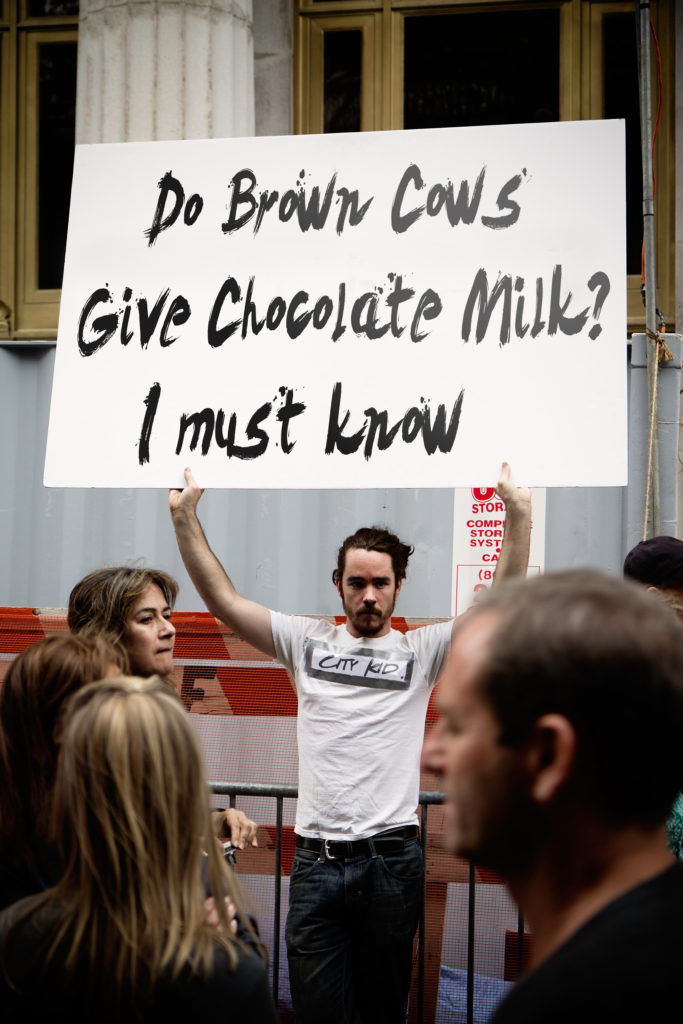

January 10, 2019No Such Thing as a Dumb Elevator Question

When you are producing a truly revolutionary product, there are often misunderstandings and communication gaps about how it works and why it is the absolute best product for the market. This is especially true when your invention was produced by thinking completely outside of the box and smashing the old-fashioned way of doing things so profoundly. Let’s face it; a lot of old-timers are more comfortable grasping buggy-whips than a new concept. So, they fight by filling people’s heads with objections and downright falsehoods. Also, there is a component of not wanting to change. Instead of looking for the best solution, copy and paste comes a lot easier and bad mouthing comes quicker than honest research, so myths are built.

The result is we get a lot of questions from people that are interested in the best elevator available for low and mid-rise applications, but they have questions that are, well, questionable because they have been so mesmerized by big elevator and modular detractors. We do have other forums we use to dispel the myths of the elevator industry. For a sample of how we have torn holes in dated premises, you can check out our two blogs, Elevator Schmelevator and Easy Up.

But for this blog post, we will cover some of the more common myths, disinformation and honest questions we have heard over the years.

Does your elevator sway in normal use?

“No. Are you crazy?” springs to mind. We think this myth comes from the fact that when engineering for earthquake-prone areas, every building (which a hoistway is often classified as) has to allow for some shaking. Our units can be completely self-supporting, so for earthquakes areas, there have to be allowances just like for any other self-supporting structure. But rest assured during normal use, our elevators that are self-supporting do not shake and if they reach a certain height for travel, they are attached to the building. There is a whole lot of engineering that has gone into the hoistways and elevators we produce. They are manufactured with steel, not spaghetti noodles, and safe in every respect.

Can your elevator be made without a pit?

This myth’s origin is easy to track down. For some, the term “modular” has the connotation to be for home, not commercial, construction, and depending on the brand of vertical conveyance, the pit depth can vary for in-home units. To contribute to the fable, our elevators have gone into some homes, but they are all commercial quality with a standard pit as required by law. So, if you have a little walking around money and want a home elevator just like you find in a commercial setting, give us a call. We will gladly produce you the fastest installing elevator, but you will need a standard four foot pit.

How can elevator construction be safer with modular?

You have to have the right tone for this question for it to make sense; incredulity and disbelief is the right way to read this. You know, like you have been doing something one way your entire life and you know there is no better way. Go ahead try it again. I see you are still struggling. Try stressing and dragging out the word “safer” and actually use air quotes with your fingers as you speak. There – now you get the tone. Now let me run the short list of why elevator construction and the work-site is safer with modular. No lifting rails, no building an elevator car one piece at a time inside the hoistway, no open doors to fall through, no scaffolding to erect, no CMU blocks to stack, no rails for counter-weights to install, no jacks to pick up and many, many more. If worker safety were really the concern of some people, all elevators for low and mid-rise would be modular. They are that safe!

Why is factory-built better?

Ahh, finally an honest question. We never roll our eyes when we hear this question because it really is the main reason to get a modular elevator instead of the old way of doing things. First, understand that the big elevator companies don’t really have an elevator factory. They have a parts facilities where they gather up what they need from other companies, produce a few things themselves and then box it all up and send them to a work-site. Think of it this way. Imagine buying a car and instead of a new Ford in your driveway, the Ford dealership drops off pallets of parts to make a car and then a mercurial technician stops by at their whim and puts the car together. You wouldn’t call it a manufactured car at all and quality would be suspect. That’s the old way of doing elevators. The right way is in a factory setting where quality is easier to manage, where consistency can be maintained, inspections take place, where the inspector can literally walk the hoistway and check rails for being level and plumb. Factory built is better.

Do you use cheaper parts?

Nope; another myth. It’s time to reveal a dirty little secret of the elevator industry. Ready? There are only a few companies that make each component of an elevator. From door openers to jacks, motors to sheaves, component companies are limited, and some of the big name brand companies make little more than nameplates. So all elevator parts pretty much come from the same manufacturers. Believe it or not, we have a part or two from a major elevator company in our elevators because in that specific case, they make a good quality part. The bottom line is that when you buy modular, there is no sacrifice in quality when it comes to the parts we use. Also, all parts always meet required codes.

A big elevator company said we needed a traction elevator for speed even though its less than ten feet of travel. Why are you recommending hydraulic?

Now we are getting to a personal bug-a-boo of mine. I hate it when people deceive to sell up. We all know what “selling up” is since McDonald’s started asking “Would you like fries with that?” The difference between McDonald’s and big elevator companies is that McDonald’s asks; they don’t act like a french fry expert and then tell people they must have golden strips of fried potato goodness due the burger code or you can only swallow your hamburger if you eat a handful of fries first. More than one person has contacted us to check if a two stop elevator with 10 feet of travel had to be traction because of speed. Really? In 10 feet, if the elevator hit its maximum speed, you would be peeling yourself off the floor. So why the up sell? Maintenance contracts. Traction elevators pull in a lot more cash each and every month. It is the same with proprietary parts. Elevators have them so elevator companies can bleed you dry in maintenance costs. Speaking of proprietary parts…

Why are you against proprietary parts?

After publishing several articles on this subject in our blogs, we got several questions about proprietary vs. non-proprietary. I got a little misty knowing that 3000+ blog visitors each month are actual humans and not bots just crawling our page. In any case, all proprietary parts do is turn the elevator owner into a hostage. The big elevator companies hold the tools and codes for repairs and will not release them. This ties the hands of the owner for the life of the unit. No matter what you do, you cannot get out of the deal and the elevator company can raise your maintenance costs at will and do maintenance and repair when they want. Unfortunately, not enough architects, GCs and building owners have learned about this game, so they will continue to be an unwilling partner or saddle end users with huge bills they can’t get out of. We never have and never will use proprietary parts. Proprietary parts are evil.

Are modular elevators approved by the government?

Our elevators meet or exceed every jurisdictional requirement for every governmental entity across the United States or Canada. From the Alaska Ice Road to Brooklyn, NY – Los Angeles, CA to Prince Edward Island, we have met codes for both the hoistway and elevators. To accomplish this, we have certified welders on staff to meet that need and we welcome outside inspectors to our factory when required. To top that off, we are also a big hit with the government itself. When you ride an elevator in many US bases and installations (we can’t say which ones), you will be in a Phoenix Modular Elevator including a fair number of VA Medical Centers. Yes, we are very much approved or can be approved in any jurisdiction.

Okay, you got me. Why doesn’t everyone insist on modular?

Ya got me, too. Everyone should. To find out pricing on a current project, just click the button below.