New Elevator

January 10, 2019

Maintenance Means Long Life

January 10, 2019Elevator Ropes – The Basics

Elevator Ropes – There are two primary types of ways an elevator moves up and down. For low-rise applications (buildings between two and four floors) hydraulic jacks are king. The jacks can be in- ground or above ground, single stage or telescopic and can provide nearly 100 feet of travel depending on the circumstances and need. They are most often the wisest choice if you are wanting to go just a couple floors or so. When you hit five floors plus you have to start looking at several different options and once your elevator requirements move beyond 100 feet there really is only one way to go and that is with a roped system. The only exception to the rule is a hybrid that uses both ropes and hydraulics (roped hydraulic).

With that said, let’s take a brief look at elevator ropes and the different types you can find in an elevator. First, keep in mind when elevator people say ropes, we are not meaning ropes that you climbed in gym class or made a lasso out of when playing Cowboys and Indians.

Elevator ropes are highly engineered and made of steel with other composites. Also they are not single wires but several strands of various sizes wrapped together. A typical cable or rope can have over 150 strands of wire precisely designed to be strong, flexible, and give long service. Multiple wire strands are used to increase the life of the cable and give flexibility. When you run a cable over a pulley wheel or sheave, the part of the wire on the sheave makes a shorter trip than the outside of the wire. This stretching over time would create weakness for a single strand. So elevator ropes are flexible strong and give long life if maintained properly. For a great resource on ropes go to the Elevator World site here!

The types of rope in an elevator can vary depending on the job that they need to do. Here are some of the more common ropes you can find lurking in your hoistway:

→ Hoisting Ropes – These are the ropes you see in all the movies. Several are used to suspend the elevator cab and make the car go up and down. These are also the cables used for the counterweights as the counterweights and elevator car are in the same system. The counterweights do just what they are called; they counter the weight of the elevator car when loaded so it takes less effort to move the car up and down. High-strength ropes are used in high rises due to the required speeds that you see today. For instance the fastest moving elevator car in the world, hits a speed that you would find on freeways; an astounding 45 miles per hour! Ultimately the grade of steel is not only determined by the speed but on the car capacity as well. The heavier the weight the car can lift, the higher strength required.

→ Governor Ropes – A governor is part of elevator safety that you will find in the hoistway or overhead space. The second that an elevator car starts falling or even rising too fast, the governor triggers the safety mounted on the car frame and brings the car to a halt. The governor rope runs over the governor sheave and down to the elevator car and is attached to the safety trip mechanism. The governor rope continues all the way down to the pit and runs under a sheave down there and then makes the journey back to the governor. This governor rope arrangement forms a continuous loop while the elevator moves up and down the hoistway. If the car starts going too fast, centrifugal force pushes flyweights outward in the governor against the spring. In simplistic terms it tells the brakes to kick in and stops the car from falling or rising too quickly. As this entire safety system relies on the governor rope, it is very important that it is reliable and in great working condition.

→ Compensating Ropes – Turns out that all of the cable or rope to make an elevator car go up and down is really heavy. This is especially true for really tall buildings. Think about this; a standard one inch elevator cable can weigh 1.85 pounds per foot. As elevator cable makes several trips up and down the hoistway, this weight can really add up. So compensating ropes “compensate” for all the weight of the hoisting ropes on the car or counterweight side. Probably any elevator that exceeds 100′ of travel needs these ropes that are connected to the sling that holds the car and the counterweight frame.

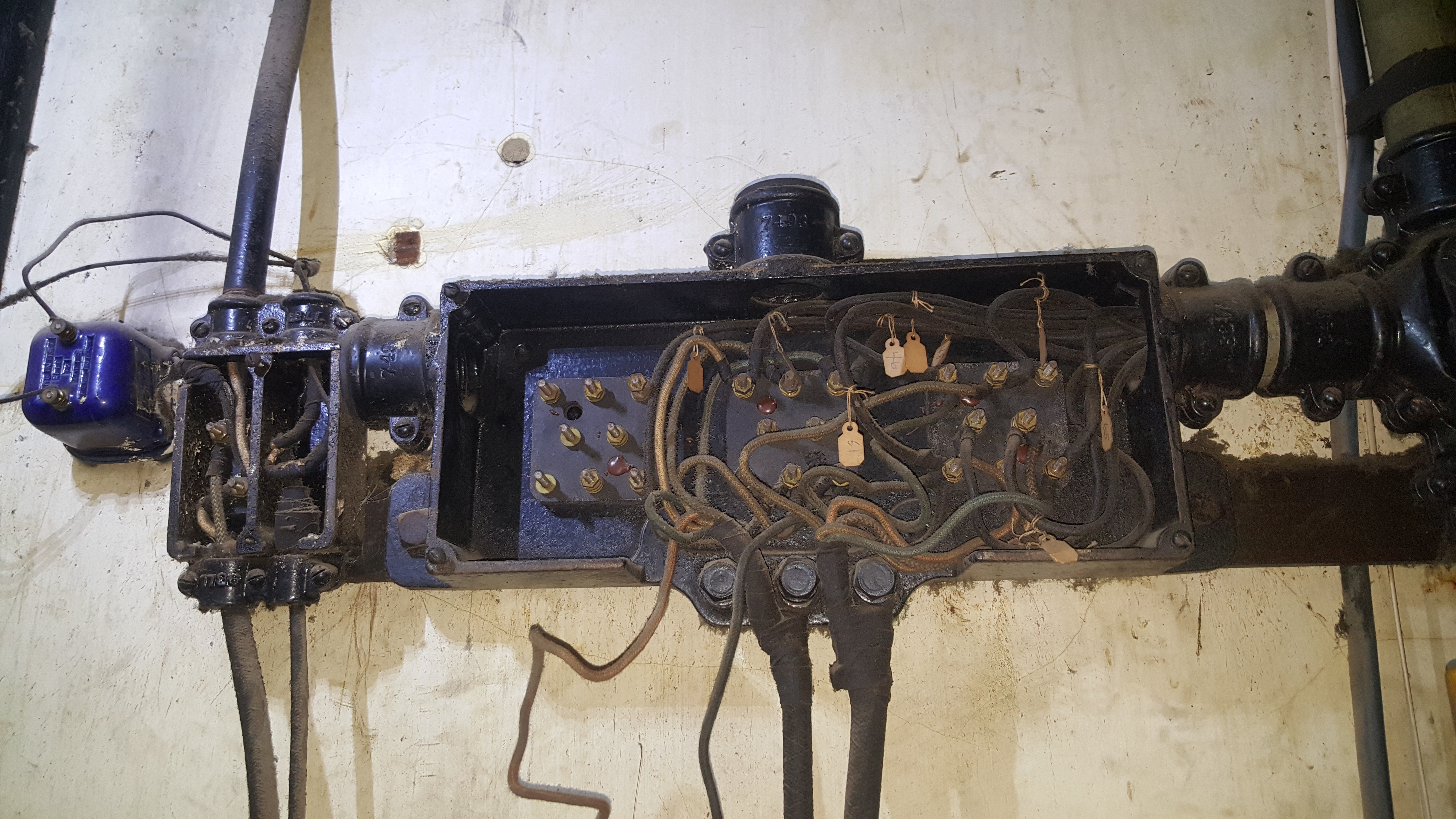

The most important thing about any elevator rope is that they must be in good operating condition at all times. This means inspected often. The technician when performing routine checks doesn’t just look up the hoistway, nod their head and move on; they must check the ropes closely for proper tension, any wear patterns, the diameter of the rope, any rusting, pitting or breaks in strands, the sheaves, proper lubrication and connections.

That is why when you go with a traction elevator, you are paying a lot more in monthly maintenance fees and also why you need to monitor the frequency of the visits and how long the mechanic is taking in the machine room, overhead, and hoistway. You are paying through the nose, so make sure they are spending their time doing what they are supposed to be doing. If you have any questions at all, discuss your elevator with an elevator consultant, work with the elevator inspector, ask them plenty of questions and discuss concerns. If all else fails, contact another independent elevator technician to check things out with an opinion as to current maintenance.