A Modular Elevator is a Better Choice

Elevators are traditionally built by laboriously constructing a hoistway as part of the building with wood, steel or concrete blocks. Components are lowered or carried into the vertical space through dangerous shaft openings or hatches. Then, they are painstakingly assembled one piece at a time.

Because this old-fashioned way takes so long and is unsafe, a more logical solution was born. Modular elevator construction literally turns elevator construction on its side in a high-quality factory environment.

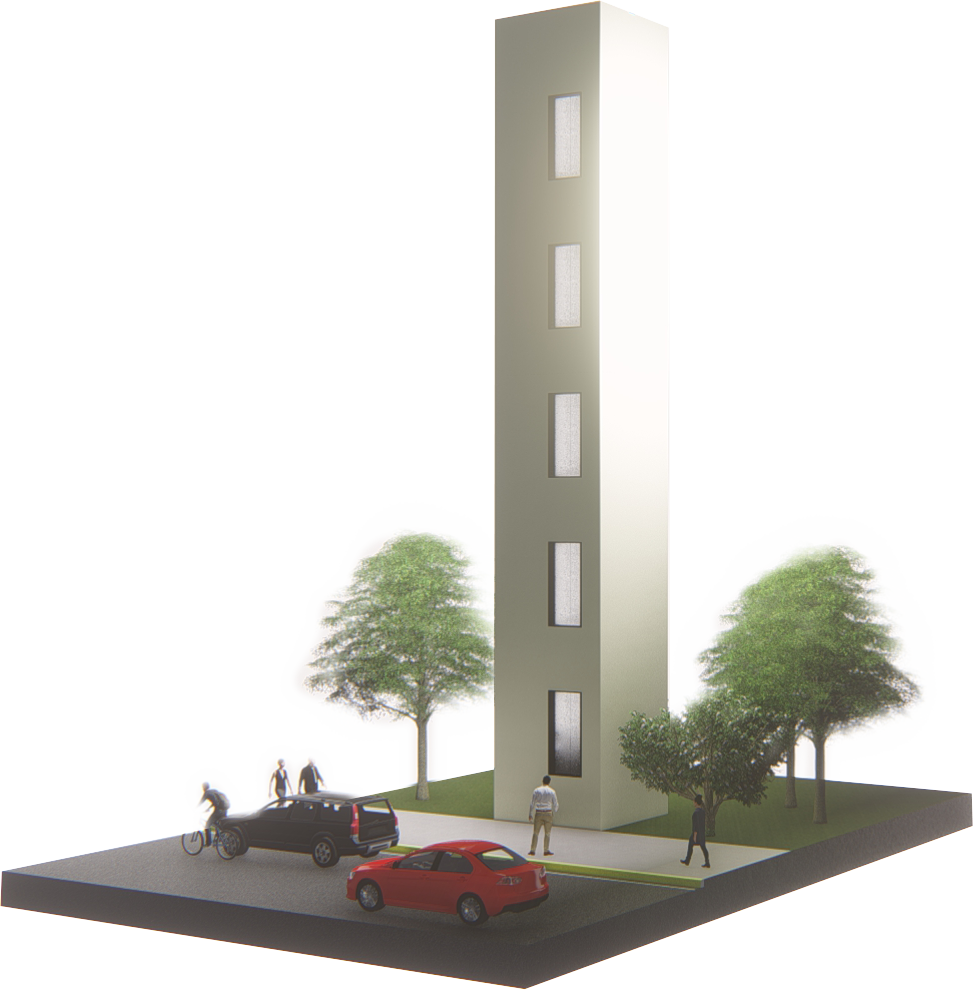

Producing elevators horizontally allows for safe and quick construction. The hoistway is a tough, durable steel frame. It is wrapped in drywall to achieve the fire-rating. The horizontal shaft then has an elevator pre-installed inside. This includes the elevator car, rails, wiring and drive system. They are complete units ready for setup, adjustment and testing. This innovative manufacturing process is a faster, safer way to build an elevator and a better choice for any structure from two to 15 stories.